CASE STUDY

Everything is smarter, even car windows, aka the self-dimming windows control

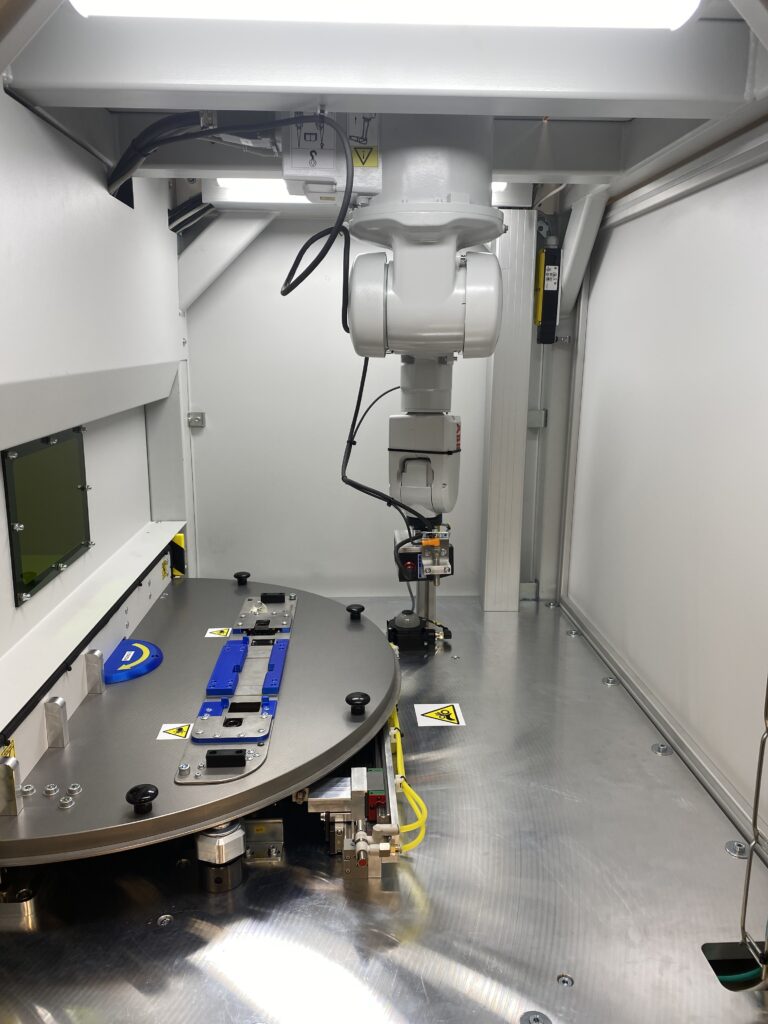

Two years ago, we were approached by a global automotive component manufacturer with a requirement to test smart glass, which they wanted to start producing. Precisely, it was testing of control units for this so called "smart glass".

During the design phase, we had discussions with several branches of the company and other suppliers, which was both challenging and interesting. In addition, we were caught in the middle of the project by Covid, and so we experienced both remote testing from a hotel where colleagues were quarantined, and separate workstations in the customer's production due to mandated isolation.

Technology

We built the software on TestStand, which the customer was already using, the communication over the LIN bus had to be connected, and the solution also included isolation testing. The interesting thing was that the customer developed the test sequence in their R&D department and we then brought it to life on a new HW that was designed for production and integrated it into the production line.

Of course, the solution was ordered in advance and we also started working on it with a large time reserve, but changes are made in every project on a customized basis and it was no different in this case, describes the project manager, Zenon Kuder:

During the design phase, we had discussions with several branches of the company and other suppliers, which was both challenging and interesting. In addition, we were caught in the middle of the project by Covid, and so we experienced both remote testing from a hotel where colleagues were quarantined, and separate workstations in the customer's production due to mandated isolation.

Technology

We built the software on TestStand, which the customer was already using, the communication over the LIN bus had to be connected, and the solution also included isolation testing. The interesting thing was that the customer developed the test sequence in their R&D department and we then brought it to life on a new HW that was designed for production and integrated it into the production line.

Of course, the solution was ordered in advance and we also started working on it with a large time reserve, but changes are made in every project on a customized basis and it was no different in this case, describes the project manager, Zenon Kuder:

What is smart glass (PDLC) and why is it called smart?

PDLC, which essentially makes smart glass smart, has the ability to randomly scatter or transmit light depending on whether an electrical stimulus is applied to it. This stimulus is usually achieved by an AC voltage that creates an alternating electric field across the PDLC material.

However, PDLC is only as smart as the control system that stimulates the change, which could be a push-button switch, a light sensor or even a building automation system. In cars, these smart windows are used for several reasons - tinting the windows when the sun is out is the main one, but they also offer sound and thermal insulation.

According to the Canadian technical server MUO (MakeUseOf), thanks to increasingly available technologies, we will see the mass use of smart glasses in 2-3 years.

"The line was ordered in advance and we also wanted to prepare things in advance, but in the meantime the specifications changed in R&D, so we were continuously adjusting some of the designs. But that's fine with us because we expect changes and we like them 😊. For the record, we have 47 items in our +/- sheet (change tracking document) for this project."

Despite various peripeties and pandemics, the project was so successful that the customer ordered the same solution again a year later, for a different type of car.

The solution offers:

- EOL testing

- Isolation resistance measurement

- Multi-system collaboration

Share this article

Facebook

LinkedIn

Download the article in pdf

Looking for a similar solution for your project? Contact us and we will get back to you to discuss the possibilities of cooperation.