Variable solution delivered within seven months of ordering

Another of our projects this year that has left the gates of our production hall to start fulfilling its purpose at the customer is an end-of-line tester of multifunctional communication modules for power circuit breakers. These circuit breakers are essential components of electrical power distribution. The customer therefore needed to determine whether the newly manufactured modules were fully functional before expedition.

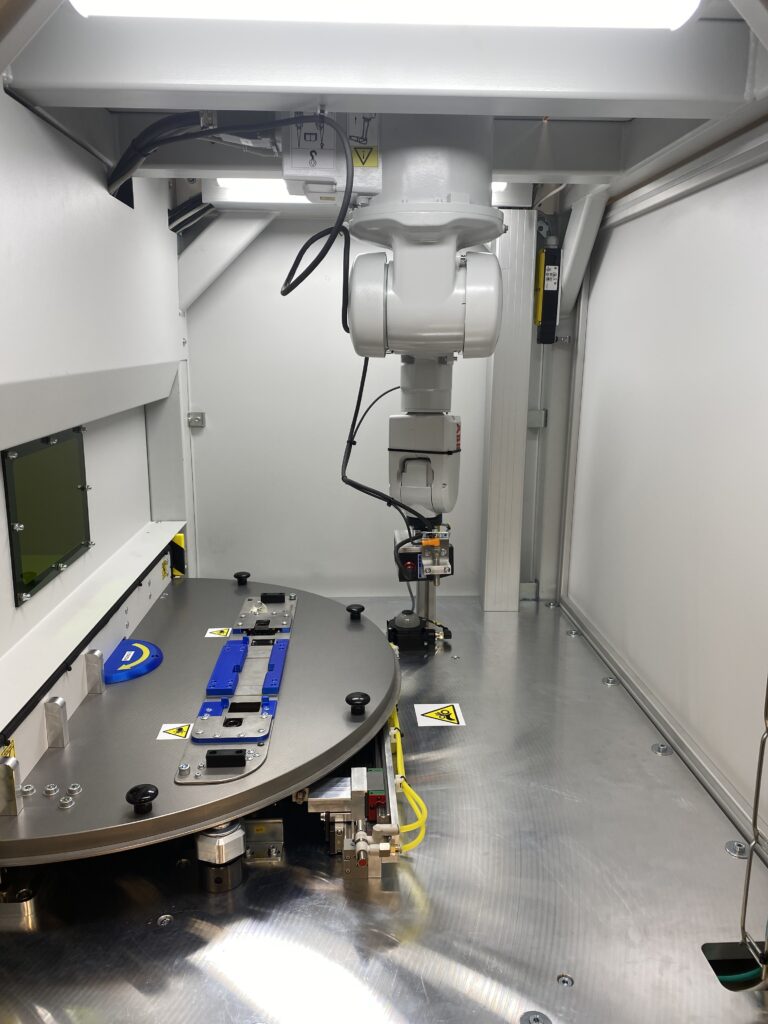

One of the functions of the modules that needed to be tested was the transmission of a Bluetooth signal. It was therefore necessary to equip the fixture with RF shielding (a metal device that serves to block or reduce electromagnetic interference in order to provide protection to components). Testing is automated and the tester operator inserts and removes products while sitting and closes and opens the fixture. Contacting individual connectors, including microUSB then works automatically, as does working with peripherals, manipulating buttons and slide switches, and measuring the color and brightness of the LED. The fixture is currently adapted to test two types of products with different combinations of interfaces and other dimensions. If necessary, the fixture can be retrofitted with additional inserts, which would make it possible to test other types of products on the same hardware.

The tester can complete all these tasks in 58 seconds.

Due to the variability of our solution and the possibility of adapting it to a wider range of types of tested products, the service we provide to the customer covers the updating of test sequences as well as possible support for adding new types of communication modules.

Share this article

Download the article in pdf

Looking for a similar solution for your project? Contact us and we will get back to you to discuss the possibilities of cooperation.